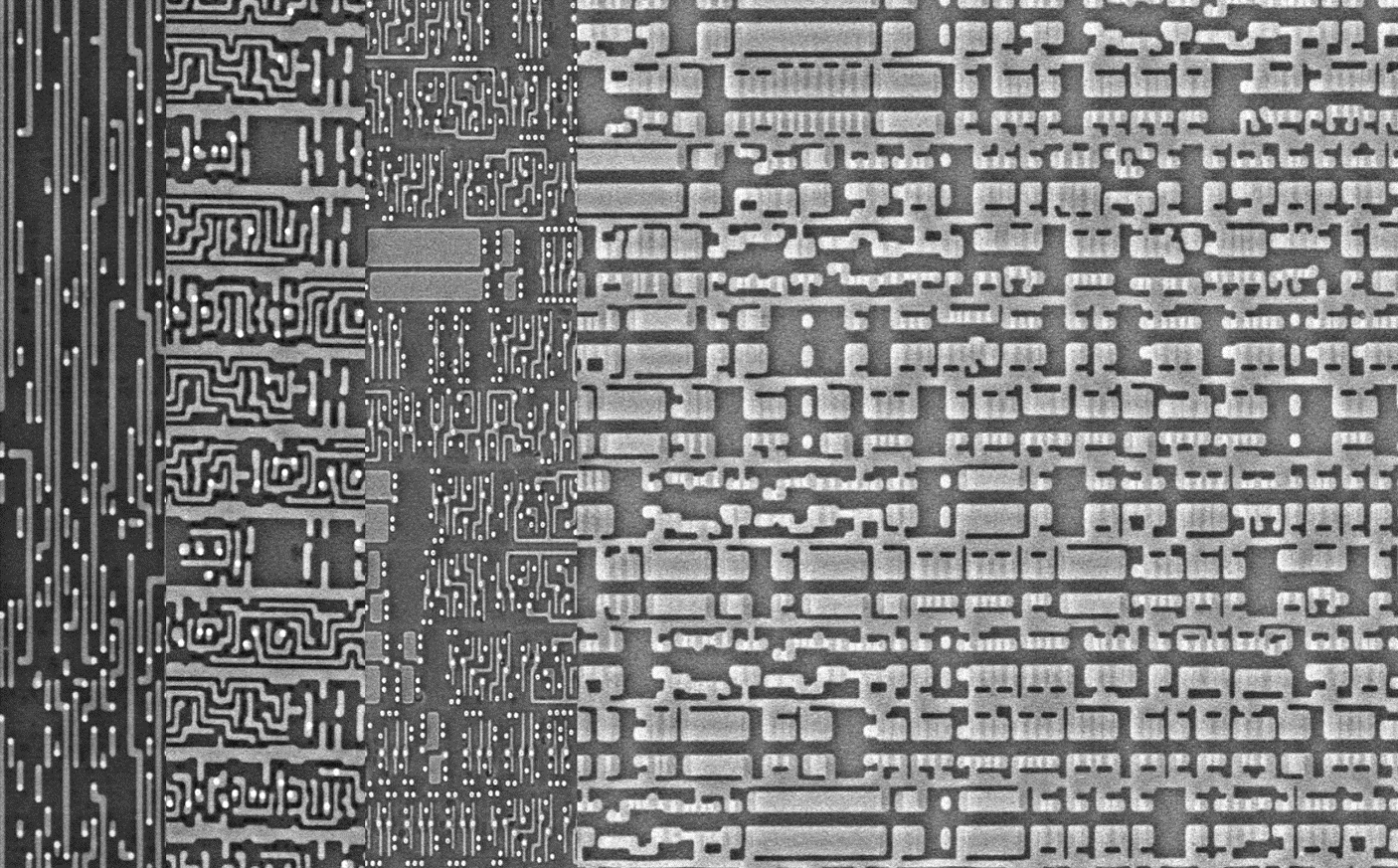

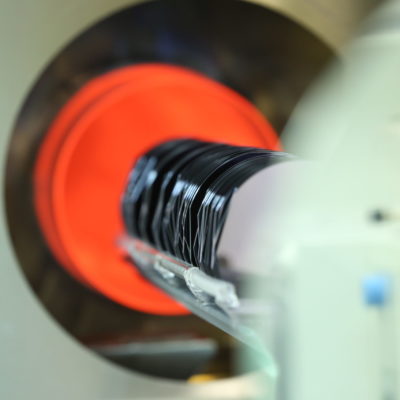

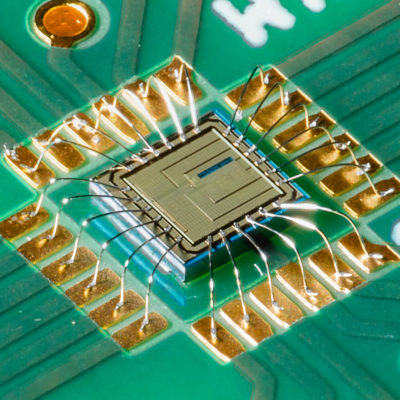

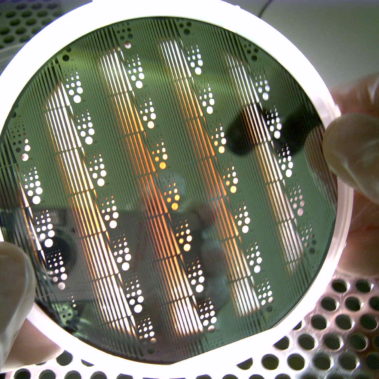

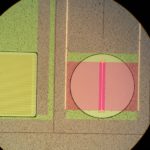

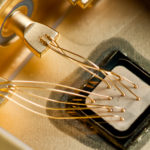

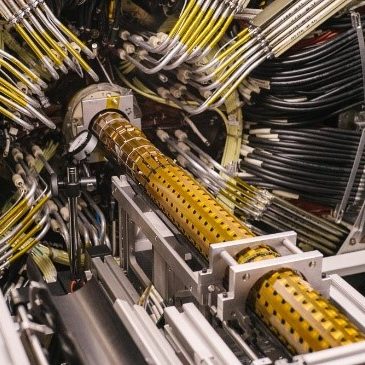

We put our facilities and our expertise at your service. We can run single processes in order to test and optimize your technologies, fabricate and characterize prototypes to study feasibility of your new ideas or managing pilot series and/or final production of your devices.

Our experience spreads in different markets, from Industrial and quality control to healthcare and medical technology, from big science experiments to space applications.

CASINO DAYS ONLINE REVIEW IN CANADA

Casino Days, founded in 2020, is a trademark of White Star B.V. with its registered office in Curacao. Casino Days is an online casino licensed and regulated by the government of Curacao to provide services in accordance with the law. The website is available in six languages: English (including Canadian, Indian, South African and New Zealand dialects), Canadian French, Norwegian, Finnish, Japanese and Thai.

The Casino Days online casino website features a variety of payment methods and games created by trusted and renowned studios. In addition, SSL technology secures the online casino and guarantees the security of the personal information and data provided.

CASINO CASINO DAYS BONUSES

Casino Days currently advertises four active promotions. There is a welcome offer that provides a 100% first deposit bonus up to C$500 and 100 free spins on Book of Dead slots. Every Tuesday, live casino players can get a reload bonus of 10% up to C$100 with a minimum deposit of C$10.

All players can participate in weekly prize draws, weekly mega draws and daily blackjack draws. Quite affordable minimum bets allow players to earn weekly prizes in the C$40-50,000 range and a daily prize pool of C$5,000. Pragmatic Play offers Drop promotions as well as Casino Days’ latest bonus offer, a monthly C$500,000 tournament with zero to C$0.50 wagering and no wagering requirements.

CASINO DAYS – LOG IN & SIGN UP

To start playing at CasinoDays CA, new players must complete a simple two-step process by clicking the blue «Sign Up» button in the upper right hand corner of your screen. The first stage requires a name, email address, password, and country, and agreeing to the Casino Days Terms and Conditions and Privacy Policy takes new users to the second stage. There, newcomers need to specify their date of birth, gender, address, city, zip code and phone number. After that, you can play for free.

VIP PLAN – CASINO DAYS

Special attention and service, cashback and priority service are all included in the VIP plan. VIPs can take advantage of weekly cashback payments of 20%, as well as special promotions, bigger bonuses and free spins with a higher value. Members can solve all problems with email and mobile-accessible customer service.

PRODUCTS AND GAMES

Casino Days offers about 4,000 games from more than 90 providers divided into several categories. At the top of the page, players can check out current popular games and new releases. Popular live games and bonus-worthy Drops & Wins are next. Then there are various types of games available, including Feature Buy, Classic Fruit slot machines, Cluster Pays and more.

LIVE CASINO AT CASINO DAYS

This casino also has an impressive Live Casino page, which also begins by offering the most popular live games. Categories based on game type: game shows, roulette, blackjack, live poker games, baccarat, craps games, lotteries, TV games and finally Andar Bahar and Tin Patty. Those live games not included in these categories, such as variations of Dragon Tiger and Lucky 7, can be found in other games located at the bottom of the page just above another subcategory called Live studio collection.

CASINO DAYS – OPTIMIZED FOR MOBILE DEVICES

All games, bonuses, and promotions are also available through the mobile version of Casino Days’ website. Players can access Casino Days and participate in games whether the gamer prefers to play on their cell phone while on the go or with the added comfort of a tablet. The only difference is that the Casino Days login and registration buttons are diagonally located in the lower left corner of the screen, rather than in the upper right corner of the desktop version.